Decarbonising aviation is one of the biggest challenges of our time, with an impact not only on aircraft design but also on airport fuelling services and more. Air travel has been around for a century and, in that time, it has primarily relied on one form of fuel: kerosene. Pre-pandemic, Europe’s airports welcomed over a billion passengers a year. How does the sector transform itself?

According to an independent study commissioned by the European Union’s Clean Aviation Joint Undertaking, novel and disruptive aircraft, engine and systems innovations, in combination with hydrogen technologies, could help to reduce the global warming effect of flying by 100% net, by 2050.

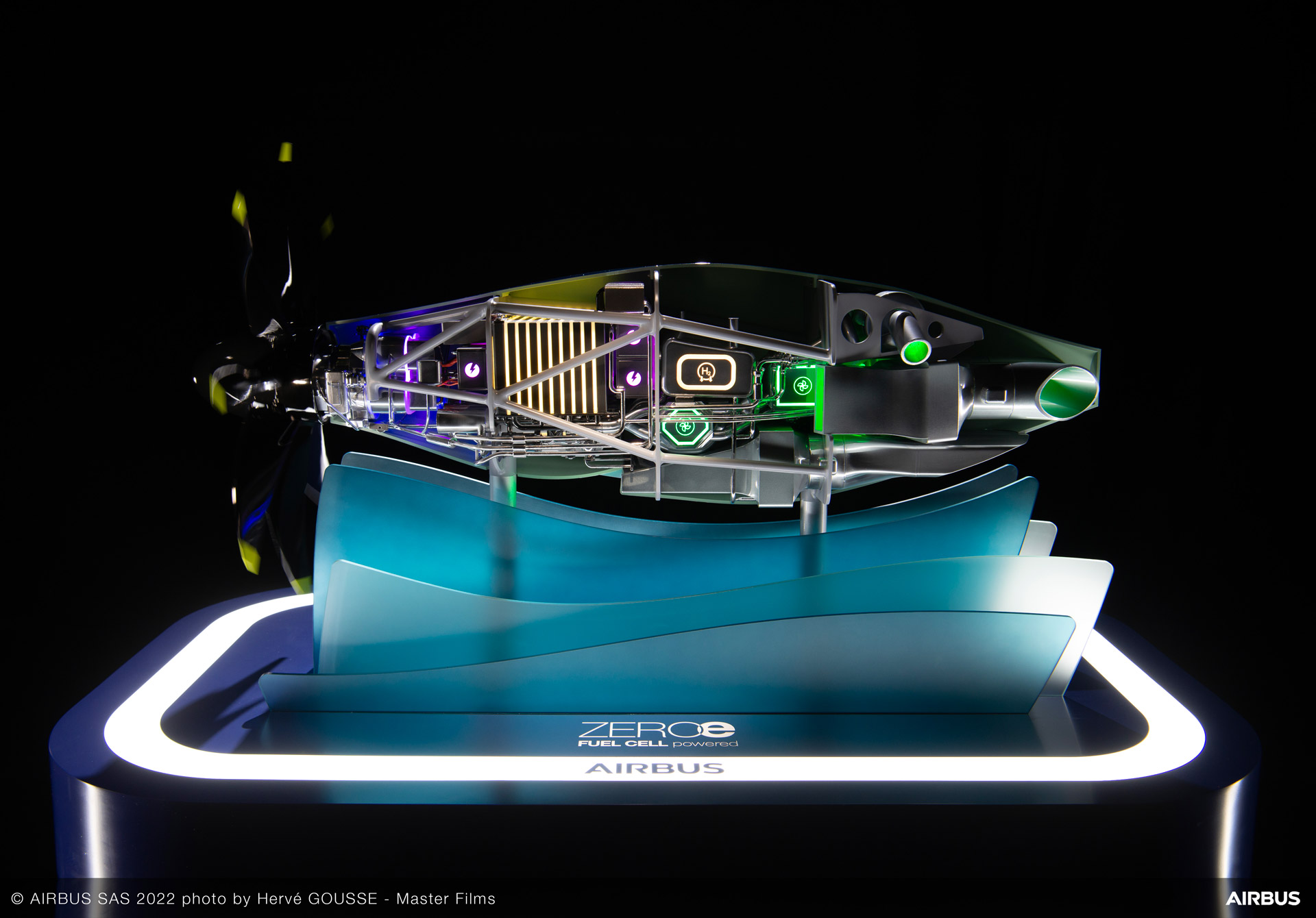

This is why Airbus has set an ambitious target of bringing a zero-emission commercial aircraft, powered by hydrogen, to market by 2035.

The hydrogen challenge

Hydrogen is a high-potential technology for aviation. When generated from renewable sources, it emits zero CO2. Significantly, it delivers around three times the energy per unit mass of traditional jet fuel and more than 100 times that of lithium-ion batteries. This makes it well suited to powering aircraft.

However, storing hydrogen onboard an aircraft poses several challenges. At normal atmospheric pressure and ambient temperature, you would need approximately 3,000 litres of gaseous hydrogen to achieve the same amount of energy as one litre of kerosene jet fuel.

Clearly, this is not feasible for aviation. To reduce volume, we can dial down the temperature to -253°C. That’s when hydrogen transforms itself from a gas to a liquid, increasing its energy density even more. Four litres of liquid hydrogen (LH2) would be equivalent to one litre of standard jet fuel.

Maintaining such a low temperature requires very specific storage tanks. Today’s tanks consist of an inner and outer tank with a vacuum in between, and a specific material, such as a MLI (Multi-Layer Insulation) to minimise the heat transfer by radiation.

To store hydrogen onboard an aircraft, more innovative creativity is needed. The development and testing of suitable LH2 tanks requires a fundamental rethink of product architectures and materials science.

For Airbus to deliver a safe, economically viable aircraft by 2035, significant efforts are needed in all fields: research and development, investment and accompanying regulation.

Joining forces to tackle the hydrogen storage challenge

After a detailed analysis of technologies used in adjacent sectors, Airbus has sought collaborations with companies with proven track records in hydrogen storage. This includes Arianespace (space applications), Air Liquide and Linde (LH2 distribution and refuelling technologies), Shell (hydrogen supply chain infrastructure), as well as ENGIE and VINCI (clean hydrogen end-to-end supply chains) to name a few.

This collaborative approach has helped to accelerate knowledge exchange on systems installation, cryogenic testing, fuel sloshing management and even on how to design and build the LH2 tanks themselves.

To further accelerate progress, Airbus took the strategic decision to develop in-house expertise in the critical areas of materials science and testing infrastructure by establishing centres of expertise, known as Zero Emissions Development Centres (ZEDCs), in France, Germany, Spain, and the UK.

In the near term, LH2 tanks are likely to be made from metal, but the long term goal is to use composite materials that will be lighter and more cost-efficient to manufacture. Equally crucial to the performance of a future hydrogen aircraft will be the end-to-end fuel systems.

Alongside Airbus’ own significant investment, financial support has been received from regional authorities, notably in Pays de la Loire, Occitanie, and Bavaria. In the future we might see support through the European Commission’s important projects of common European interest (IPCEI).

A new prototype LH2 tank – ready for testing

Phase One of the project has been completed successfully. For the first time, a LH2 tank has been designed and built in Europe – only one year into the programme.

These tanks are now prepared for rigorous testing, but we can already say that the work carried out at the ZEDCs is going a long way to de-risk the use of hydrogen in commercial aircraft operations. It is expected to provide a very significant benefit to the broader aerospace ecosystem, including for airlines and airports, as well as the wider supply chain.

The knowledge gained could also support the wider transport sector, including road haulage, trains and shipping, as well as adjacent industries that consider hydrogen as a way to decarbonise their activities, including high-value chemicals and heavy industries such as steel and cement.

Unlocking hydrogen’s potential

Airbus is fully committed to developing the world’s first zero-emission commercial aircraft by 2035 – and to the significant investment and cross-industry collaborations that are and will be necessary within an incentivising policy framework.

We believe that hydrogen has the potential to make this vision a reality – but there is one major caveat: Our success depends on the availability of sufficient quantities of cost-competitive hydrogen from low-carbon sources, powered by renewable or nuclear energy.

With increased public and private support, leveraging flagship initiatives such as the Clean Aviation Research Partnership and the Alliance for Zero-Emission Aviation, the technology pathways can be de-risked more quickly.

With commitment from Airbus, and the whole stakeholder community, the hydrogen revolution for aviation is becoming a reality.